Processes

Processing adds value

Reich’s expertise in mechanics, metallurgy, assembly and knowledge of the finished end product offers the flexibility required to respond to customer requests in a timely and professional manner.

Using cutting-edge production technology supports the continuous development and modification of our manufacturing methods and processes. Our technical skills include metallurgical, mechanical and thermal product treatment.

Efficient work cycles, reduced fitting and changeover times further contribute to the reliable and punctual provision of goods of consistently high quality.

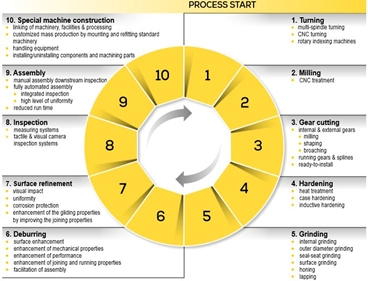

Process illustration

Metallurgical, mechanical and thermal processes and techniques.

Our processes:

- turning

- milling

- gear cutting

- hardening

- grinding

- deburring

- surface refinement

- plastic injection molding

- assembly

- special machine construction

- inspection